Thermal management is a critical concern for modern electronics, industrial applications, and consumer devices. Devices get smaller, more powerful, and require more energy as technology advances. However, this has also led to increased heat production, making efficient cooling systems more important than ever. This is where custom vapor chambers are revolutionizing thermal management. By leveraging advanced heat-spreading capabilities, custom vapor chambers are helping companies like Tone Cooling Technology Co., Ltd. redefine what it means to keep electronics cool in an efficient, compact, and sustainable way.

Advanced Cooling Technologies

The Rising Heat Challenges in Modern Electronics

The amount of heat produced by electronic equipment rises in tandem with their performance. High-performance processors, graphics cards, and power-hungry devices such as electric vehicles (EVs) and gaming consoles demand cutting-edge cooling solutions to ensure they continue to function efficiently without the risk of overheating.

Traditional cooling methods, such as fans, heatsinks, and heat pipes, have worked well for decades, but they no longer offer the same level of efficiency as today’s devices require. With shrinking spaces and higher thermal outputs, the demand for more efficient thermal management solutions has become crucial.

Why Traditional Cooling Methods Fall Short

While fans and heat sinks can dissipate heat, they rely on air movement to transfer the heat away from the device, which can be inefficient in certain conditions. Heat pipes are more effective, but they still have limitations in terms of heat spreading and their ability to manage high thermal loads consistently. Moreover, these methods often occupy valuable space within the device, adding bulk and weight.

Enter custom vapor chambers—a game-changing technology that offers an efficient, compact, and highly effective solution to thermal management challenges.

Enter the Custom Vapor Chamber

A custom vapor chamber is a highly advanced thermal management device designed to address the limitations of traditional methods. Using a combination of phase change and heat-spreading technologies, vapor chambers provide a more efficient solution for dissipating heat across a larger surface area, ensuring even heat distribution and enhancing overall device performance.

What Is a Custom Vapor Chamber?

The Science Behind Vapor Chambers

At its core, a custom vapor chamber is based on a simple but highly effective principle: phase change. Inside the chamber, a small amount of liquid is heated, causing it to vaporize into gas. This vapor moves to cooler areas of the chamber where it condenses back into a liquid, releasing the absorbed heat. This process is highly efficient in spreading heat evenly across the surface area of the device.

Phase Change Technology Explained

The phase change cycle involves the liquid inside the vapor chamber evaporating when exposed to heat. The heat is released when the vapor rises to the cooler top of the chamber and condenses back into liquid form. The cycle repeats itself there, where the liquid then returns to the chamber’s hot spot. This mechanism ensures that the heat is evenly distributed, preventing localized hotspots from forming.

Heat Spreading with Maximum Efficiency

One of the standout features of custom vapor chambers is their ability to spread heat quickly and efficiently. The use of advanced materials and design customizations allows these chambers to dissipate heat over large areas, ensuring that no part of the device becomes excessively hot. This is especially crucial for high-performance electronics, where heat management is a key factor in maintaining long-term performance and reliability.

How Customization Changes the Game

Custom vapor chambers can be created to meet particular device requirements, which sets them apart from standard vapor chambers. Whether it’s adjusting the size, shape, or internal design of the chamber, custom vapor chambers can be engineered to fit the unique needs of any application. This customization allows for optimal heat management, ensuring that devices perform at their peak without the threat of overheating.

Key Components of a Custom Vapor Chamber

-Wick Structures and Their Role

The wick structure is one of a vapor chamber’s most crucial components. It consists of a network of capillary channels that help return the condensed liquid to the hot spot. These channels can be made from various materials, and the design of the wick is critical in ensuring the efficiency of the phase change cycle. Customizing the wick structure is one way to optimize the performance of a vapor chamber based on the specific heat requirements of the device.

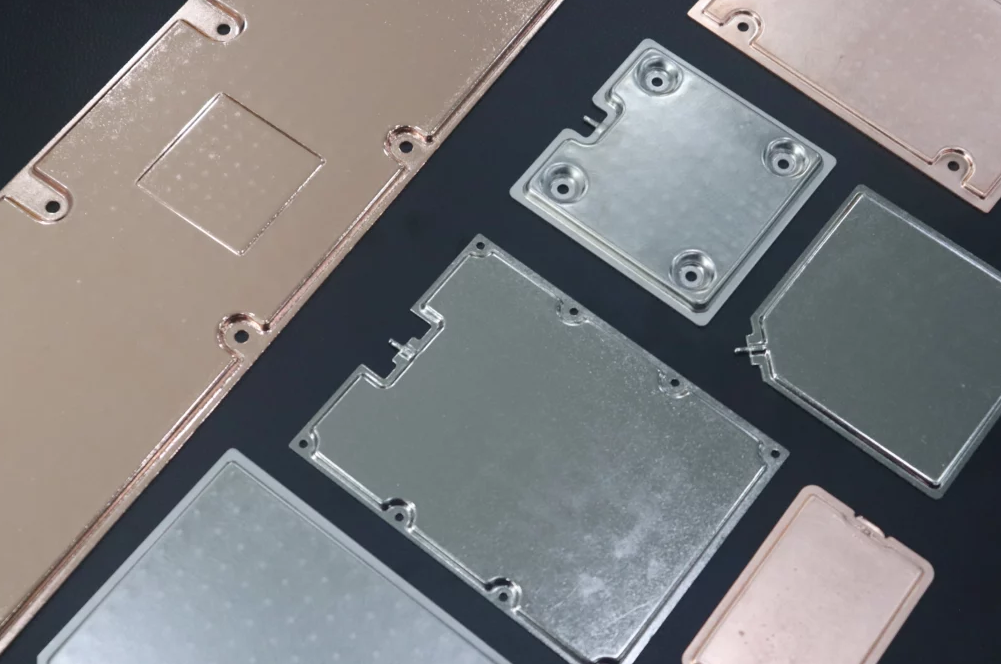

-Vapor Spaces and Material Choice

The vapor chamber’s materials also affect its performance greatly. The inner surfaces of the chamber are typically made from materials with high thermal conductivity, such as copper or aluminum, to facilitate efficient heat transfer. By selecting the right material for the vapor space, manufacturers can enhance the performance and durability of the vapor chamber.

-How Geometry Impacts Thermal Conductivity

The geometry of the vapor chamber itself is also customizable. Whether the chamber is designed to fit inside a smartphone, a gaming console, or a high-performance server, its shape and size can be adjusted to maximize its heat dissipation capabilities. A well-designed geometry ensures that heat is distributed efficiently and that the vapor chamber can handle the thermal loads placed on it by high-performance components.

Why Customization Matters in Thermal Management

-Tailoring for High-Performance Applications

Customization is key in meeting the specific thermal management needs of high-performance applications. From gaming devices to electric vehicles, each application has its own unique heat dissipation requirements. Custom vapor chambers allow manufacturers to tailor the cooling solution to suit the precise needs of the device, ensuring that it operates efficiently without overheating.

-Fit-for-Purpose vs. One-Size-Fits-All

While off-the-shelf vapor chambers may work for basic applications, they often fall short when it comes to high-performance devices that require precise cooling solutions. Custom vapor chambers are designed to meet the unique challenges posed by specific devices, offering enhanced performance and greater reliability.

-Durability and Environmental Considerations

Additionally, customization enables the addition of components and features that increase the vapor chamber’s robustness. Whether it’s resistance to harsh environmental conditions or extended lifespans for high-use applications, custom vapor chambers can be designed to meet the exact demands of the device.

Benefits of Using Custom Vapor Chambers

-Superior Heat Dissipation

One of the main benefits of using a custom vapor chamber is its superior heat dissipation capabilities. By spreading heat evenly across a larger surface area, custom vapor chambers can prevent overheating and ensure that devices operate within safe temperature ranges, maximizing their efficiency and lifespan.

-Lightweight and Compact Designs

Custom vapor chambers are designed to be light and compact, in contrast to traditional cooling systems, which can be bulky and heavy. They are therefore ideal for applications like smartphones, wearables, and electric vehicles where space and weight are important.

-Energy Efficiency and System Longevity

Custom vapor chambers can also contribute to energy efficiency. By efficiently managing thermal loads, they help devices maintain optimal performance without requiring additional energy to power cooling systems, such as fans or liquid cooling pumps. This leads to longer system lifespans and reduced energy consumption.

Applications Across Industries

-Consumer Electronics: Phones, Laptops, Tablets

In the consumer electronics industry, devices like smartphones, laptops, and tablets are constantly being pushed to deliver higher performance in smaller, thinner packages. Custom vapor chambers provide an excellent solution for dissipating heat efficiently, ensuring that these devices remain cool and operate smoothly under demanding conditions.

-Automotive and Electric Vehicles (EVs)

Electric vehicles generate significant heat during operation, especially in their powertrains and battery systems. Custom vapor chambers play a vital role in managing these thermal loads, helping to ensure the safety and performance of EVs. By efficiently managing heat, custom vapor chambers contribute to better battery performance and longevity.

-Aerospace and Defense Systems

In aerospace and defense applications, thermal management is critical for the performance and safety of electronic systems used in satellites, drones, and military equipment. Custom vapor chambers are designed to operate under extreme conditions, providing effective cooling in environments where traditional methods would fail.

-Industrial Machinery and Robotics

Industrial machinery and robotics often operate in harsh environments where heat generation is a concern. Custom vapor chambers can be designed to withstand these conditions, ensuring that systems remain functional and efficient. Their ability to dissipate heat over large surfaces is crucial for maintaining system integrity in these industries.

Challenges and Considerations in Vapor Chamber Design

-Design Complexity and Cost

While custom vapor chambers offer significant advantages, their design and manufacturing process can be more complex and expensive compared to traditional cooling methods. The custom design process requires careful consideration of factors such as material choice, geometry, and the device’s specific thermal needs. As a result, custom vapor chambers are often a higher upfront investment than standard cooling solutions.

However, given the long-term benefits, including enhanced device performance and longevity, the investment in custom vapor chambers can pay off for high-end applications and devices.

-Size and Space Constraints

Although custom vapor chambers are compact, their design must still take into account the size constraints of the device they’re cooling. In smaller devices, space is often limited, making it challenging to incorporate an efficient vapor chamber without compromising on other components. For this reason, careful engineering is required to ensure that the vapor chamber fits within the device while still providing optimal cooling performance.

The Future of Custom Vapor Chambers

-Advancements in Materials and Technology

The technology behind custom vapor chambers is continually evolving. Advances in materials such as nanomaterials and advanced heat spreaders are enhancing the thermal performance of vapor chambers. Additionally, the integration of smart technologies that monitor temperature fluctuations and adjust the cooling mechanisms accordingly could become standard in the future, allowing for even more efficient heat management.

As companies like Tone Cooling Technology Co., Ltd. continue to innovate in this space, we can expect further improvements in the versatility, efficiency, and performance of custom vapor chambers.

-Wider Adoption Across Emerging Markets

The demand for effective cooling solutions will only rise in tandem with the growing demand for more compact, powerful electronics. Custom vapor chambers are likely to see widespread adoption not only in consumer electronics but also in emerging markets such as electric vehicles, wearables, and even the growing field of augmented reality (AR) and virtual reality (VR).

The ability to efficiently manage heat in these next-generation devices will be critical to their success, and custom vapor chambers are well-positioned to meet these demands.

-Sustainability and Eco-Friendly Designs

Sustainability is becoming an increasingly important factor in product design across all industries. Custom vapor chambers, by their very design, help reduce energy consumption by efficiently managing heat and preventing devices from overheating. As manufacturers continue to innovate, there will likely be a focus on incorporating more eco-friendly materials into the production of vapor chambers. This shift could further enhance their appeal to environmentally conscious consumers and industries.

In a world where electronics are getting more powerful and compact, custom vapor chambers represent the next frontier in thermal management. By offering superior heat dissipation, enhanced performance, and quiet operation, these cooling solutions are transforming how companies approach thermal management. The ability to customize vapor chambers for specific devices means that manufacturers can ensure their products perform at their best, even under the most demanding conditions.

As we look toward the future, the advancements in vapor chamber technology promise even greater efficiency, sustainability, and versatility. Leading the way with creative solutions that are assisting in redefining the potential of thermal management are businesses such as Tone Cooling Technology Co., Ltd.

FAQs

What is a custom vapor chamber and how does it work?

A sophisticated thermal management tool for effectively distributing heat across a device’s surface is a customized vapor chamber. It works through a phase change process, where a liquid inside the chamber evaporates due to heat, moves to cooler areas, and condenses back into liquid form, thereby dissipating the heat.

Why are custom vapor chambers important for modern electronics?

More heat is produced by smaller and more potent devices. Custom vapor chambers help to effectively manage this heat, ensuring that the device performs optimally without overheating, which can lead to malfunction or reduced lifespan.

How are custom vapor chambers different from traditional cooling solutions?

Unlike fans and heat sinks, which rely on air to dissipate heat, custom vapor chambers use phase change technology to spread heat efficiently over a large surface area. This makes them more effective for managing high thermal loads and ideal for compact, high-performance devices.

What industries can benefit from custom vapor chambers?

Industries such as consumer electronics (smartphones, laptops), automotive (electric vehicles), aerospace, robotics, and even gaming are increasingly adopting custom vapor chambers for their thermal management needs.

Are custom vapor chambers cost-effective?

While custom vapor chambers can be more expensive upfront due to their design complexity, their long-term benefits—such as improved device performance, longevity, and energy efficiency—make them a worthwhile investment, particularly for high-performance applications.