Investing in a shrink wrap machine can be a game-changer for businesses looking to enhance packaging efficiency, product protection, and presentation. Whether you’re a small business or a large-scale manufacturer, shrink-wrapping offers a cost-effective way to seal and safeguard products.

However, many buyers make the mistake of focusing only on the upfront cost of the machine while overlooking several hidden expenses that can impact their long-term budget. Before purchasing a shrink wrap machine for sale, it’s crucial to understand these unexpected costs to make an informed decision.

Here are seven hidden costs of shrink wrap machines that buyers often fail to consider.

Shrink Film Costs: The Silent Budget Drainer

A shrink wrap machine is useless without the right shrink film, and this is where many buyers underestimate the ongoing costs.

Shrink film comes in different materials, including polyolefin, PVC, and polyethylene, each with varying costs and applications. For example, if you’re wrapping food products, you’ll need FDA-approved polyolefin film, which is more expensive than standard PVC.

Film thickness (measured in mils or gauges) also affects cost and durability. Thicker films provide better protection but also increase material expenses over time.

Maintenance and Repairs: The Unavoidable Expense

Like any industrial equipment, shrink wrap machines require regular maintenance to keep them running efficiently. Parts such as:

✔ Heating elements (for heat tunnels and sealers)

✔ Conveyor belts (for automatic machines)

✔ Sealing wires and blades

… will wear out over time and need replacements.

Some manufacturers offer warranties, but these often exclude wear-and-tear parts. If you don’t budget for maintenance, you could face costly downtime when your machine inevitably needs servicing.

Labor Costs: Manual vs. Automated Operations

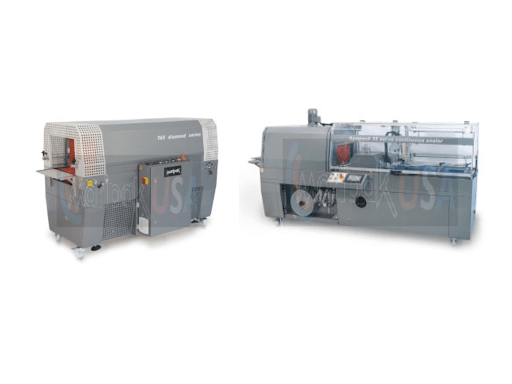

Shrink wrap machines come in manual, semi-automatic, and fully automatic models. While an automatic machine can significantly reduce labor costs, semi-automatic and manual machines still require human intervention.

For instance, a manual shrink wrap machine requires an operator to place and seal each item individually, which can slow down packaging and increase staffing expenses.

If your packaging volume is high, investing in an automated system may be more cost-effective in the long run.

Space Requirements: The Cost of Floor Space

Shrink wrap machines vary in size, and buyers often underestimate the amount of space needed to operate them effectively.

For example, heat tunnels and large sealing machines require ample space for loading, sealing, and cooling zones. If your warehouse or workspace is limited, you may need to rearrange storage areas or lease additional space, leading to unexpected costs.

Electricity Consumption: A Hidden Utility Cost

Shrink wrap machines consume more electricity than most buyers anticipate, especially heat tunnel models that require continuous high temperatures to shrink the film effectively.

Some machines, such as semi-automatic L sealer machines, use infrared heating to improve efficiency but still require significant power. Over time, this can lead to higher utility bills, especially for businesses running multiple shifts.

Training Costs: Getting Your Staff Up to Speed

Even the most user-friendly shrink wrap machines require proper training to operate efficiently. Without it, businesses often experience:

-

Material waste from improper film application

-

Production slowdowns due to incorrect heat settings

-

Inconsistent sealing, leading to product damage

Some manufacturers offer free training, while others charge a fee for on-site or virtual training sessions. Either way, training is essential to avoid costly mistakes.

Compliance & Safety Costs: Meeting Industry Standards

Shrink wrapping, especially for food, pharmaceuticals, and electronics, must meet industry regulations for safety and hygiene.

For instance, food-grade shrink film must comply with FDA and USDA standards, and pharmaceutical products may need tamper-evident packaging. Some businesses may also need to invest in ventilation systems using shrink wrap film that releases fumes.

Ignoring compliance could lead to fines, recalls, or product rejections, making this an indirect but significant cost.

Final Thoughts

When searching for a shrink wrap machine for sale, looking beyond the sticker price is crucial. By understanding these hidden expenses, you can make an informed purchase that aligns with your budget and long-term operational goals. Planning for these often-overlooked expenses can maximize your investment and ensure seamless shrink-wrapping operations for years.