In today’s fast-paced world of product innovation, getting an electronics product from concept to market requires more than just technical know-how—it demands a precise and proven development process that minimizes risk and maximizes quality. For companies seeking reliability, speed, and compliance in electronics design, aligning with the right development partner can make all the difference.

Electronics design is a multifaceted process that stretches from early-stage ideation to manufacturing and compliance. Each phase carries its own challenges and risks, and without experienced guidance, projects can quickly spiral out of scope or fall short of performance standards. This is where a structured approach becomes crucial.

A solid design process begins with understanding the client’s vision, market requirements, and technical specifications. At this stage, clarity around goals and constraints ensures alignment before deeper technical work begins. From there, the process typically moves into system architecture, detailed design, prototyping, and validation—all stages that must be carried out with precision and accountability.

The true test of a product’s viability, however, lies in its transition from design to manufacturing. It is during this critical phase that many projects experience delays or unexpected costs due to overlooked compliance issues or design inefficiencies. By identifying and communicating risks throughout the project timeline, a seasoned design partner can help companies avoid these pitfalls and stay on track.

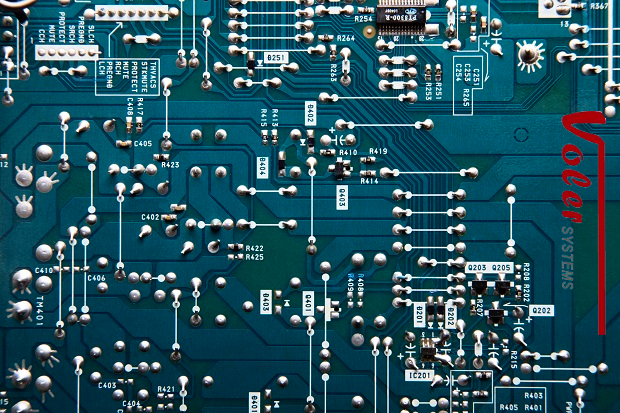

One of the leading experts in this space is Voler Systems, a company known for delivering quality electronics design services that are on time, on budget, and low risk. Their experienced team supports clients through every step of the product lifecycle, from initial concept through to regulatory compliance and final manufacturing transfer. What sets them apart is their commitment to identifying potential risks early and guiding projects to successful outcomes with transparency and precision.

A hallmark of any successful design service provider is their ability to adapt to various industries and applications. Whether working on medical devices, consumer electronics, industrial automation, or IoT products, the principles of careful planning, iterative development, and rigorous testing remain the same. A disciplined yet flexible methodology allows for innovation without compromising on reliability.

Moreover, the regulatory landscape for electronics continues to evolve. With increasingly stringent requirements for safety, electromagnetic compatibility (EMC), and environmental standards, companies must design with compliance in mind from the start. A failure to do so can result in costly redesigns, certification failures, or delayed product launches. A trusted partner ensures that the final product not only performs well but also meets all applicable industry standards.

In conclusion, success in electronics design isn’t just about building a functioning device—it’s about delivering a fully compliant, manufacturable product that performs reliably in the real world. By working with a proven and experienced team, companies can bring their innovations to market faster, more efficiently, and with confidence.

If quality, compliance, and on-time delivery are critical to your next electronics project, choose Voler Systems-the right partner could be your smartest move.