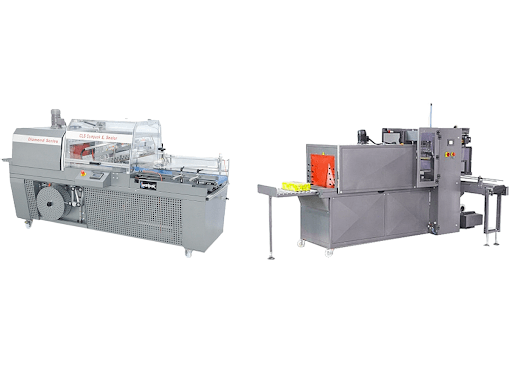

In today’s fast-paced manufacturing and distribution industries, packaging plays a crucial role in both product presentation and protection. Businesses are under increasing pressure to ensure their packaging processes are not only effective but also time-efficient and cost-saving. Among the wide range of packaging machinery available, L bar sealer machines have emerged as a smart and dependable solution for businesses of all sizes.

Designed to streamline shrink wrapping and sealing, L bar sealers combine speed, simplicity, and precision—making them an ideal choice for companies that prioritize efficiency without compromising on quality. Whether you’re packaging food, electronics, cosmetics, or printed materials, these machines can handle the task with ease and consistency.

What is an L Bar Sealer Machine?

An L bar sealer is a type of packaging equipment used to seal products in shrink film. The machine gets its name from the L-shaped sealing bar that cuts and seals the film in two directions—creating a closed pouch around the product. Once sealed, the package is typically passed through a heat tunnel or shrink chamber, which causes the film to shrink tightly around the item.

This method provides a clean, professional look while also safeguarding the product from dust, moisture, and tampering. L bar sealers are especially popular in operations that require high-volume packaging with consistent results.

Key Features That Make L Bar Sealers a Smart Investment

L bar sealers offer a range of features that make them appealing for businesses looking to upgrade or automate their packaging processes. Let’s explore what sets them apart from traditional or manual sealing systems.

High-Speed Performance

Time is money in any production environment. L bar sealers are engineered for high-speed operation, enabling users to seal dozens—or even hundreds—of products per hour. Semi-automatic and fully automatic models offer touchless sealing capabilities, increasing throughput and minimizing labor requirements.

Precision and Clean Seals

These machines are designed to deliver clean, consistent seals every time. Adjustable temperature settings, sealing time, and pressure controls ensure that each package is tightly and evenly sealed without burns or wrinkles in the film. This precision improves the presentation of products and enhances their shelf appeal.

Versatile Packaging Capabilities

L bar sealers are compatible with a variety of shrink films, including polyolefin, PVC, and polyethylene. This versatility allows businesses to package a wide range of products, from books and cosmetics to hardware and perishable goods. Adjustable sealing bars also accommodate different product sizes and shapes without requiring frequent changeovers.

Minimal Operator Training Required

Another major advantage is ease of use. Most L bar sealers feature user-friendly control panels and intuitive operation, meaning minimal training is required. This makes them ideal for businesses that experience seasonal staff changes or need to ramp up production quickly.

Cost-Effectiveness

By automating the packaging process and reducing material waste, L bar sealers contribute to long-term cost savings. The machines also reduce labor costs by minimizing manual intervention. Over time, this investment can lead to a significant improvement in operational efficiency and profitability.

Common Applications Across Industries

L bar sealer machines are widely used in many sectors, each with unique packaging needs. Their versatility makes them suitable for:

-

Retail Packaging: Creating tamper-evident, clean-looking packages for retail displays.

-

Food Industry: Sealing bakery items, frozen foods, or snack packs in a hygienic, visually appealing way.

-

Publishing: Wrapping books, magazines, or brochures in protective film.

-

Pharmaceuticals: Ensuring safe and contamination-free packaging of medical supplies.

-

Electronics: Securing sensitive devices or accessories with protective shrink film.

Regardless of the industry, L bar sealers provide a consistent packaging solution that meets both aesthetic and functional requirements.

Conclusion

L bar sealer machines are a smart and strategic investment for businesses seeking to enhance packaging efficiency, product protection, and presentation. With their blend of speed, precision, and versatility, these machines are well-suited for industries ranging from food and retail to pharmaceuticals and electronics.

For businesses aiming to streamline operations and improve output quality, switching to an L bar sealer offers tangible benefits that go beyond aesthetics. By optimizing your packaging process, reducing waste, and saving time, these machines empower you to stay competitive in a demanding marketplace.

Whether you’re a small business scaling up or a large operation seeking automation, buying the right packaging machinery for sale can lead to smarter, faster, and more cost-effective packaging solutions.