In today’s rapidly advancing biomedical and clinical laboratory environments, automation plays a crucial role in improving efficiency, precision, and productivity. One essential piece of equipment that supports these goals is the ELISA plate washer. These systems are specifically designed to streamline the washing process in ELISA (Enzyme-Linked Immunosorbent Assay) protocols, ensuring consistent results while significantly reducing manual errors. With the availability of multiple channel options, modern ELISA plate washers are tailored to meet a wide range of throughput and procedural requirements, making them indispensable in automated laboratory settings.

The Role of an ELISA Plate Washer in Modern Laboratories

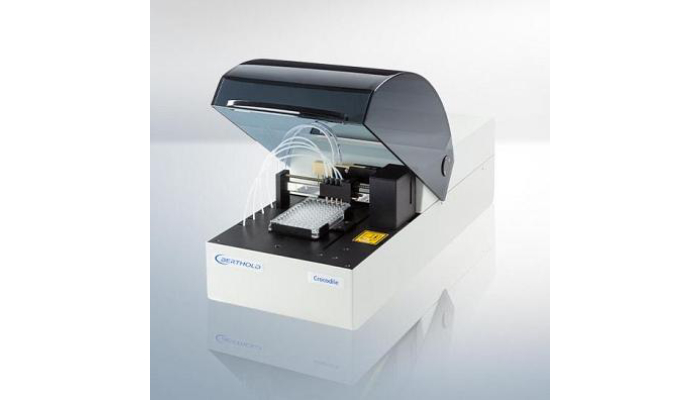

The ELISA plate washer is a laboratory device used to rinse microplates in ELISA assays by automatically dispensing and aspirating washing solutions in a controlled and repeatable manner. These devices have become integral to laboratories focusing on diagnostic testing, pharmaceutical research, biotechnology development, and academic research.

Manual washing methods, although still in use in smaller labs, often lack the precision, reproducibility, and time-efficiency required in high-throughput environments. In contrast, an ELISA plate washer ensures uniform washing across all wells, which is essential for reducing background noise, minimizing cross-contamination, and enhancing assay sensitivity.

Importance of Multiple Channel Options in ELISA Plate Washers

One of the most valuable advancements in the design of an ELISA plate washer is the integration of multiple channel options. These channels refer to the number of dispense and aspirate heads that interact with the wells of the microplate. Most standard ELISA plates come in 96-well or 384-well formats, and the ability of the washer to address multiple wells simultaneously can drastically influence throughput.

A 1-channel washer is suitable for low-volume work or specialized applications. However, higher channel configurations—such as 8, 12, or 16 channels—allow simultaneous washing of multiple wells, significantly speeding up the process. Laboratories that deal with large sample volumes or time-sensitive assays benefit immensely from ELISA plate washers with multi-channel configurations, as they reduce hands-on time and free up personnel for other critical tasks.

How ELISA Plate Washers Improve Workflow Efficiency?

Workflow optimization is at the heart of laboratory automation, and a high-performance ELISA plate washer directly contributes to this objective. By automating the tedious and repetitive task of plate washing, these machines reduce the variability introduced by manual methods. With programmable settings for soak time, dispense volume, wash cycles, and aspiration speed, ELISA plate washers can be fine-tuned to meet the specific needs of various assays.

Additionally, ELISA plate washers with advanced channel configurations allow laboratories to process several plates in rapid succession or even simultaneously, thereby increasing throughput. When integrated into a complete automated system that includes plate readers and robotic arms, an ELISA plate washer helps maintain a smooth and continuous workflow from sample preparation to data analysis.

Key Features to Look for in an ELISA Plate Washer

When selecting an ELISA plate washer, several critical features should be considered to ensure it meets the operational demands of your laboratory:

- Multiple Channel Configuration: Choose a model that offers the right number of channels to match your assay volume and speed requirements.

- Compatibility with Plate Formats: Ensure the washer is compatible with 96-well, 384-well, or other formats used in your laboratory.

- Adjustable Washing Parameters: Look for customizable settings such as wash cycles, aspiration height, and dispensing volume to enhance assay performance.

- Low Residual Volume: A quality ELISA plate washer leaves minimal residual liquid, which is vital for accurate assay readings.

All these features combine to enhance the efficiency, accuracy, and reproducibility of ELISA testing, making them essential for any modern laboratory.

Advantages of Using ELISA Plate Washers in Automation

The integration of an ELISA plate washer into a laboratory’s automated workflow offers numerous advantages:

- Consistency: Automating the wash step removes human variability, resulting in more reliable and repeatable results.

- Time-Saving: High-throughput processing with multi-channel washers significantly reduces the time required for large batches of samples.

- Cost Efficiency: Although the initial investment may be substantial, long-term savings in labor, reagents, and reduced repeat assays justify the cost.

- Reduced Contamination Risk: Automated washing reduces the risk of sample contamination from manual handling.

- Improved Data Quality: Proper washing leads to cleaner results with lower background noise, contributing to more accurate analysis and better decision-making.

Laboratories that regularly perform ELISA assays benefit from the automation and precision of an ELISA plate washer, ensuring consistent output even in high-volume scenarios.

Applications Across Laboratory Settings

The versatility of the ELISA plate washer makes it suitable for a wide variety of laboratory applications. In clinical diagnostics, it supports testing for infectious diseases, hormones, and autoimmune markers. In pharmaceutical research, it plays a crucial role in drug discovery and pharmacokinetics by aiding in biomarker quantification. Biotechnology companies use ELISA plate washers for quality control, ensuring batch-to-batch consistency in their products.

Academic and government research institutions also benefit from using automated washers to increase productivity in studies involving immunology, microbiology, and cell biology. The ELISA plate washer’s ability to enhance precision and throughput makes it a valuable tool in any setting where ELISA is a core analytical method.

Maintenance and Care for Long-Term Use

To maximize the performance and longevity of your ELISA plate washer, routine maintenance is essential. This includes:

- Regular Cleaning: Flush the internal tubing and channels with distilled water after use to prevent clogging.

- Scheduled Calibration: Periodic calibration ensures accurate dispensing and aspiration.

- Inspection of Components: Check and replace worn-out parts such as seals, valves, and washers to prevent leaks and malfunctions.

- Software Updates: Keep firmware and software interfaces up to date to benefit from improved functionality and bug fixes.

A well-maintained ELISA plate washer delivers consistent performance and minimizes costly downtime, which is critical in high-demand laboratory environments.