In modern laboratories, assay automation has revolutionized how researchers and scientists perform complex experiments, especially in fields like biotechnology, pharmaceuticals, and diagnostics. The demand for faster, more accurate, and reproducible results has made manual processes less viable. As a result, assay automation platforms are now integral to lab operations. However, selecting the right assay automation system can be a daunting task. There are numerous factors to consider to ensure that the platform aligns with your lab’s current needs and future growth. This guide explores key features you should evaluate when choosing an assay automation platform, helping you make an informed decision for enhanced productivity and precision.

Compatibility With Existing Lab Infrastructure

One of the first things to consider when evaluating an assay automation platform is its compatibility with your existing lab infrastructure. Integration is key. Your current laboratory instruments, software, and workflow protocols must align with the new automation system. For example, can the automation platform communicate effectively with your liquid handlers, incubators, and detection devices? Seamless compatibility ensures that your lab doesn’t face disruptions or require significant additional investments. Additionally, the ability to integrate with laboratory information management systems (LIMS) and data analytics tools should be assessed to support streamlined data handling.

Flexibility And Scalability Of The Platform

Flexibility is a crucial factor in any assay automation solution. Laboratories evolve—whether it’s adding new assays, changing methodologies, or scaling operations. The platform should offer modular components and configurable software to accommodate changing requirements. A flexible system allows you to switch between different assay formats, handle varying sample volumes, and customize workflows without major reconfigurations. Furthermore, scalability ensures that as your workload increases, the automation platform can be upgraded to handle higher throughput without a complete system overhaul. This future-proofing aspect is essential for labs aiming for long-term growth.

User-Friendly Software Interface

Another key consideration in assay automation is the usability of the software interface that drives the system. A complex user interface may require extensive training and can lead to errors in protocol execution. Look for platforms that offer intuitive, drag-and-drop interfaces with clear visual workflow builders. The software should allow for easy programming, real-time monitoring, and quick troubleshooting. Enhanced user experience leads to reduced operator fatigue and increases the likelihood of consistent and error-free operations. Moreover, built-in data analysis and reporting features can further enhance productivity and accuracy.

Precision, Accuracy, And Reproducibility

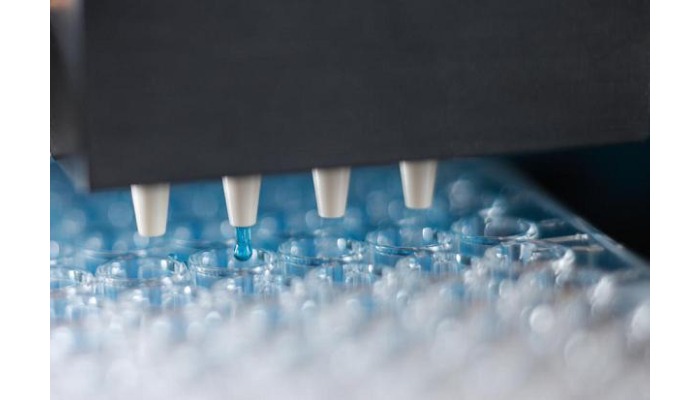

The very reason laboratories turn to assay automation is to improve precision, accuracy, and reproducibility. The platform must deliver consistent pipetting, incubation, mixing, and detection capabilities. This ensures that results are not only accurate but also reproducible across multiple runs and users. Evaluate the system’s track record for minimizing variability and handling sensitive assay conditions. High-performance robotics with precise calibration and low error margins are vital. Additionally, look for platforms that offer real-time environmental monitoring, such as temperature and humidity control, which can directly influence assay outcomes.

Throughput Capabilities And Speed

Throughput and processing speed are essential for high-demand laboratories. Depending on the nature of your work, your assay automation needs may range from low throughput for small research projects to high throughput for commercial screening. The chosen platform should match your expected sample load without bottlenecks. Automation systems designed for rapid sample processing often include multi-channel pipetting, parallel task execution, and smart scheduling features. Evaluate cycle times, plate capacity, and system responsiveness. This ensures your laboratory meets deadlines while maintaining assay integrity and performance.

Data Management And Traceability

Data is at the core of all scientific work, and robust data management is a must in assay automation platforms. Look for systems that offer secure data logging, comprehensive audit trails, and compliance with regulatory standards such as 21 CFR Part 11. The ability to trace every step of the assay—from sample loading to result generation—is invaluable for reproducibility and quality control. Efficient data storage and retrieval systems also streamline reporting and collaboration. Data traceability not only improves lab efficiency but also supports regulatory audits and quality assurance processes.

Customization And Protocol Development

Every laboratory has unique needs, and a rigid assay automation platform may not suffice. Platforms that allow users to create, modify, and optimize their assay protocols offer a significant advantage. Custom protocol development ensures that the automation system can adapt to novel or specialized assays. Features such as open scripting environments, user-defined templates, and adjustable workflow parameters give users complete control. This level of customization helps researchers push the boundaries of scientific discovery without being limited by the automation technology itself.

Maintenance, Support, And Reliability

Reliability is a cornerstone of any investment in assay automation. Downtime can severely impact research timelines and output. Choose platforms with a solid reputation for reliability and minimal maintenance needs. Additionally, assess the availability of technical support, service contracts, and spare parts. A good automation partner should offer comprehensive training, remote diagnostics, and quick on-site servicing. Preventive maintenance features such as self-cleaning mechanisms and error diagnostics contribute to consistent operation and extended system lifespan.

Safety Features And Compliance

Safety is a critical yet often overlooked aspect of assay automation. Automated systems must incorporate safety features to protect both operators and samples. This includes secure enclosures, emergency stop mechanisms, and contamination prevention protocols. Furthermore, the platform should comply with international safety and quality standards. Compliance with Good Laboratory Practices (GLP), ISO certifications, and local regulatory requirements should be confirmed. Ensuring operator safety and sample integrity supports the long-term credibility of your lab’s output and protects your investment.

Conclusion

Choosing the right assay automation platform is more than a technological decision—it’s a strategic investment that directly influences your laboratory’s efficiency, scalability, and innovation capacity. From compatibility and scalability to software usability and compliance, every feature plays a vital role in the overall performance of the automation system. Taking the time to assess your lab’s specific needs and thoroughly evaluate available features will ensure you select a platform that not only meets current demands but also adapts to future advancements in scientific research. In a rapidly evolving scientific landscape, well-implemented assay automation serves as the backbone of success, driving precision, productivity, and innovation.