The demand for faster deliveries, better customer experiences, and more streamlined operations has led to the widespread adoption of automation in fulfillment centers. One of the key players driving this transformation is the belt conveyor system. These systems, which have long been a staple of manufacturing and logistics, have become essential in handling the enormous volume of packages that flow through modern fulfillment centers. In this blog, we’ll explore how automation, powered by belt conveyors, is shaping the future of e-commerce fulfillment centers and what that means for the industry’s evolution.

The Role of Belt Conveyors in E-Commerce Fulfillment Centers

Belt conveyors are integral to modern e-commerce fulfillment centers, providing a fast, efficient, and reliable method for moving goods through various stages of the order process. From receiving inventory to sorting, packaging, and shipping, belt conveyors help manage the heavy lifting of transferring products from one area to another, reducing human labor and enhancing operational efficiency.

As e-commerce continues to grow, fulfillment centers are expected to handle ever-increasing volumes of orders. Automation technologies, especially belt conveyor systems, are crucial in meeting these demands. These conveyors not only streamline workflows but also ensure that products are moved safely and quickly through the facility. By automating these processes, fulfillment centers can reduce bottlenecks and enhance the overall speed of their operations.

How Automation is Enhancing Efficiency with Belt Conveyors

One of the primary benefits of using automated belt conveyors in e-commerce fulfillment centers is the significant improvement in processing speed. In traditional warehouses, goods would often need to be manually transferred from one point to another. This not only required a large workforce but also introduced the possibility of errors and inefficiencies.

Today, automated belt conveyors can move items seamlessly through various stages of the fulfillment process. From picking and sorting to packaging, these systems help streamline workflows and minimize the likelihood of errors. For instance, once a product is picked, a belt conveyor can automatically transport it to a sorting area where it’s organized based on its final destination. This level of automation reduces the need for manual handling, freeing up workers to focus on more complex tasks and minimizing the likelihood of human error.

Additionally, the integration of sensors and smart technology into belt conveyor systems enhances the automation process. These systems can now detect when an item is on the conveyor and make real-time adjustments to the conveyor’s speed and direction. This allows for dynamic handling, ensuring that the flow of goods is optimized throughout the fulfillment center.

Belt Conveyors and the Integration of Packaging Machines

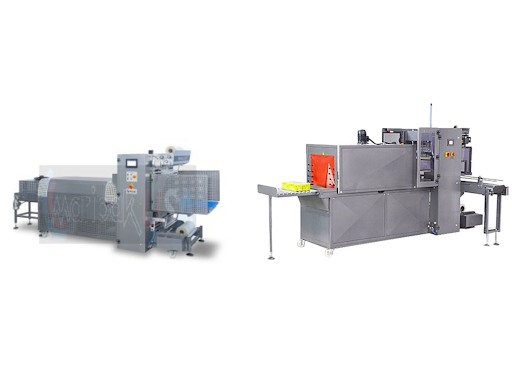

In modern e-commerce fulfillment centers, the automation of the packaging process has become a crucial component of the workflow. Belt conveyors play a crucial role in this process by seamlessly integrating with packaging equipment. After an item is sorted on the conveyor, it can be automatically fed into a packaging machine that is capable of wrapping, labeling, and sealing the package without requiring human intervention.

The use of automated packaging devices reduces the time spent on packaging and increases the overall throughput of the fulfillment center. Conveyor systems are designed to move products in a way that aligns them perfectly with the machines, ensuring accurate and efficient packaging every time. The integration of belt conveyors with packaging appliances has been a game-changer for e-commerce companies, enabling them to meet customer demands for faster delivery times while maintaining high levels of accuracy and consistency in the packaging process.

Conclusion

Automation powered by belt conveyors is revolutionizing e-commerce fulfillment centers. As the demand for faster deliveries and more efficient processes grows, these systems will continue to play a pivotal role in improving operational efficiency. The integration of smart technologies, AI, and packaging machines into belt conveyor systems is elevating automation to new heights, enabling fulfillment centers to stay competitive in an increasingly demanding market. The future of belt conveyors in e-commerce appears promising, with continuous innovation driving efficiency, accuracy, and speed throughout the supply chain.