Introduction to Automated Material Handling in Warehouse Management

Efficiency is paramount in warehouse management, where every second counts. Automated material handling systems have emerged as indispensable tools for redefining efficiency and productivity in warehouse operations. This article explores how automated material handling is revolutionizing warehouse management.

The Role of Automated Material Handling in Warehouse Operations

Automated material handling systems play a pivotal role in warehouse operations by automating the movement, storage, and retrieval of goods. These systems enable warehouses to manage inventory, fulfill orders, and optimize storage space with unparalleled speed, accuracy, and efficiency.

Key Components of Automated Material Handling Systems

Key components of automated material handling systems in warehouse management include:

- Conveyors and Sortation Systems: These systems transport goods between different areas of the warehouse, facilitating efficient flow and distribution.

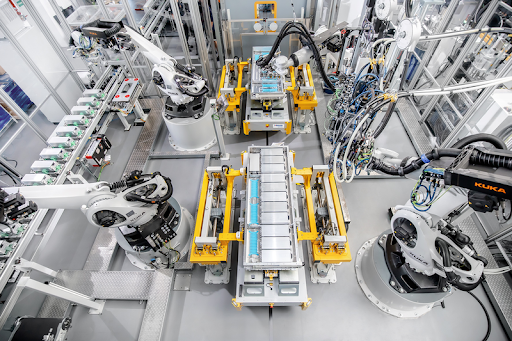

- Automated Storage and Retrieval Systems (AS/RS): AS/RS solutions utilize robotic technology to store and retrieve items from high-density storage locations, maximizing space utilization and minimizing retrieval times.

- Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles that transport goods within the warehouse, reducing the need for manual labor and increasing operational flexibility.

- Warehouse Management Systems (WMS): WMS software provides real-time visibility and control over warehouse operations, enabling efficient order management, inventory tracking, and resource allocation.

Applications of Automated Material Handling in Warehouses

Automated material handling systems find applications across various warehouse processes, including:

- Receiving and Putaway: Automated systems streamline the receiving and putaway processes by automatically identifying, sorting, and storing incoming goods.

- Order Fulfillment: Automated systems enable efficient order picking, packing, and shipping, reducing fulfillment times and improving customer satisfaction.

- Inventory Management: Automated systems provide real-time visibility and control over inventory levels, enabling warehouses to optimize stock levels and reduce carrying costs.

- Cross-Docking: Automated systems facilitate cross-docking operations by efficiently transferring goods from inbound to outbound docks, minimizing storage times and handling costs.

Benefits of Automated Material Handling in Warehouse Management

The adoption of automated material handling systems offers several benefits for warehouse management:

- Increased Productivity: Automated systems operate continuously and perform tasks with greater speed and accuracy than manual labor, leading to higher productivity and throughput.

- Improved Accuracy: Automated systems reduce errors and discrepancies in warehouse operations, resulting in improved order accuracy and inventory control.

- Cost Savings: Automated systems reduce labor costs, minimize product damage, and optimize space utilization, leading to overall cost savings and improved profitability.

- Enhanced Safety: Automated systems reduce the risk of workplace accidents and injuries associated with manual material handling, creating safer and healthier work environments for warehouse personnel.

Challenges and Solutions

While automated material handling systems offer significant benefits, warehouses may encounter challenges such as:

- Initial Investment: The upfront costs associated with implementing automated systems can be substantial, requiring careful financial planning and justification.

- Integration Complexity: Integrating automated systems into existing warehouse operations and infrastructure may require technical expertise and thorough planning to ensure seamless integration.

- Maintenance and Support: Automated systems require regular maintenance and support to ensure optimal performance and uptime, necessitating ongoing investment in training and resources.

Future Trends in Automated Material Handling

Looking ahead, the future of automated material handling is marked by several key trends, including:

- Advanced Robotics: Continued advancements in robotics technology will enable the development of more sophisticated and versatile material handling solutions, capable of handling a wider range of tasks and environments.

- Integration with IoT and AI: Integration with the Internet of Things (IoT) and artificial intelligence (AI) will enable automated systems to collect and analyze data in real-time, enabling predictive maintenance, optimization, and decision-making.

- Modular and Scalable Solutions: Modular and scalable automated systems will enable warehouses to adapt to changing demands and scale their operations efficiently, without the need for significant capital investment.

Conclusion

In conclusion, automated material handling systems are transforming warehouse management by enhancing efficiency, accuracy, and safety. By embracing these systems and addressing associated challenges through innovation and collaboration, warehouses can gain a competitive edge and thrive in the dynamic and demanding logistics landscape.

FAQs

- What is automated material handling in warehouse management? Automated material handling involves using automated systems to manage the movement, storage, and retrieval of goods within a warehouse, streamlining operations and increasing efficiency.

- What are the key components of automated material handling systems in warehouses? Key components include conveyors, sortation systems, AS/RS, AGVs, and WMS software.

- What are the benefits of automated material handling in warehouse management? Benefits include increased productivity, improved accuracy, cost savings, and enhanced safety in warehouse operations.

- What challenges are associated with automated material handling in warehouses? Challenges include initial investment costs, integration complexity, and maintenance and support requirements.

- What are the future trends in automated material handling? Future trends include advancements in robotics, integration with the IoT and AI, and the development of modular and scalable solutions to meet the evolving needs of warehouses.

- https://deltasigmacompany.com/